NIKUNI multi-phase flow mixing pumps have been widely used in the water treatment industry for many years, playing an important role in upgrading water treatment technology and equipment. At the same time, NIKUNI multi-phase flow mixing pumps have also shown great potential in many new applications in other industries, solving the technical and process problems that users have been worrying about for many years and verifying the application value and capabilities of NIKUNI products.

一. CHARACTORISTICS:

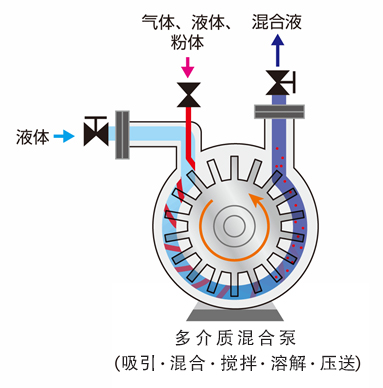

- The most significant feature of the NIKUNI multi-phase flow mixing pump is that it sucks in liquid and other different media that need to be mixed at the same time and have them uniformly mixed and blended by the pump impeller and pressurized and sent to the outlet pipeline. The conveying pressure generated inside the pump delivers the finely mixed medium to a distant point of use.

- NIKUNI multi-flow mixing pump is multifunctional and compared with traditional equipment in the field of water treatment applications gas ejectors, air compressors, large dissolved gas tanks and discharge discs become unnecessary. In the application fields of chemical and other industries it can replace reaction tanks, mixing and blending equipment and complex pipelines, valves, and control systems, greatly simplifying the application process and equipment structure.

- The use of NIKUNI multi-phase flow mixing pumps helps to reduce equipment power consumption, minimize equipment failures, improve mixing efficiency, and make related equipment performance more stable and reliable.

- Compared with traditional equipment, NIKUNI multi-media mixing pump helps reduce initial investment costs, long-term operating costs and maintenance costs.

Product Applicability

1. Liquid to liquid mixing 1. Mixing of liquid and gas (dissolution, reaction, neutralization)

◎ Mixing and dissolution of air

Generate fine bubbles for use in dissolved air flotation, product cleaning or entertainment facilities, etc.

◎ Mixing and dissolution of oxygen Aquaculture, hydroponic cultivation of crops, oxygenation, etc

◎ Ozone gas dissolution to water

Aquaculture, hydroponic cultivation of crops, oxygenation, etc

◎ Ozone gas dissolution to water

Production of ozone water (sterilization, removal of organic matter), etc

Mixing and dissolution of various gases

Producing functional beverage water such as oxygen rich water and hydrogen rich water

1. Liquid to liquid mixing (mixing of immiscible liquids)

Emulsification of water and fuel oil

◎ Polymer flocculant dilution

◎ Chemical process application

Reaction, neutralization, dispersion, emulsification, homogenization, etc

33. Mixing of powder and liquid(dispersion, dissolution)

●Food processing industry

Defatted milk powder, wheat flour, skimmed milk powder, wheat flour, corn starch, soy milk, etc

◎ Chemical raw materials

Coagulants, polymers, calcium carbonate, etc

3、 Practical application cases

◎ Water+air (oxygen)

Hydroponic cultivation of crops and plants, providing water and oxygen supply to the roots of plants grown in greenhouses

Iron removal from well water

Oxygen supply to aquaculture ponds, cages, and ornamental fish tanks

Activation of aerobic bacteria in the purification tank and aeration tank filled with acetic acid

Circulating water for spraying workstation, oxygenation and anti-corrosion of cutting fluid for cutting machine tools

.

◎ Water+Ozone

Sterilization of fruits, vegetables, river seafood, meat, and kitchenware

Sterilization of circulating water such as drinking water, beverages, swimming pools, and bathhouses

Removing chemical residues in semiconductor production processes

Sterilization and cleaning in the production process of biologics and pharmaceuticals

Deodorization of pig pens, chicken coops, various exhaust devices, etc

Sludge reduction during biological treatment process

◎ Seawater+Air (Oxygen)

Promote growth during the breeding process of flounder, oysters, fresh shellfish, etc

◎ Water+Carbonated Gas

Neutralization of chemical solution during alkaline waste liquid treatment and boiler descaling process

Promotes the growth of aquatic plants Large ornamental fish tank

.

.

◎ Water+Hydrogen

Reduce chemical night residues in semiconductor cleaning process

◎ Seawater+Ozone

Sterilization of seawater, shellfish, seagrass, fishing gear, containers, etc

◎ Chemical liquids + various gases

Reaction and coincidence inside the pipeline (such as photocatalyst, calcium carbonate, etc.)

◎ Water+Nitrogen

remove dissolved oxygen from ultra pure water and nitrogen for boiler water supply

◎ Powder+Liquid (Food Processing)

Production of skimmed milk powder, wheat flour, corn starch, soy milk, etc

◎ Powder+Liquid (Chemical Raw Materials)

Production of coagulants, polymers, calcium carbonate, etc

Conclusion:

NIKUNI multi-phase flow mixing pump is suitable for various applications such as gas-liquid mixing, liquid-liquid mixing, powder liquid mixing, etc. Using a NIKUNI mixing pump to add various functional gases such as oxygen, nitrogen, ozone, carbon dioxide, hydrogen, chlorine, etc. to fresh water, seawater, and chemical liquids, allowing them to fully dissolve and mix with the liquids, can add new value to the water and liquids. It also plays a positive role in the emulsification of liquids and the refining of fuels. Can replace static mixers. It plays a role in the mixing process of powder and liquid in food production and chemical raw material production.