How does liquid ring compressor work

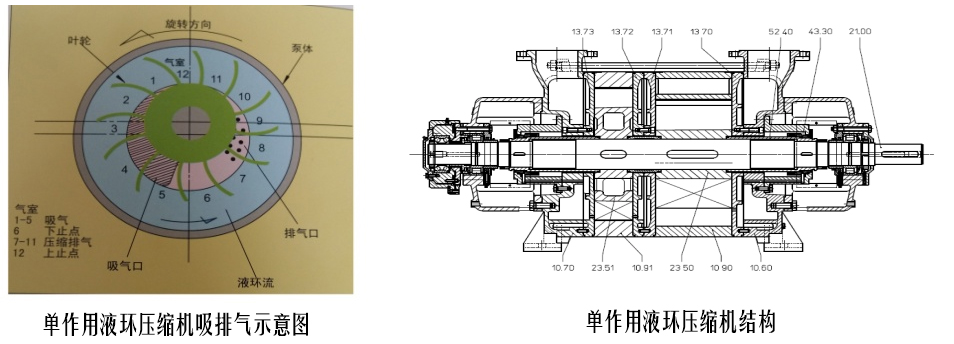

The common liquid ring compressor is the same as the liquid ring vacuum pump, with its impeller eccentrically installed inside the housing. Under the centrifugal force of the high-speed rotating impeller, the sealing liquid inside the shell forms a closed liquid ring along the inner wall. The flat port plate installed inside the liquid ring compressor housing is equipped with a semi-circular suction port and compression port for gas. These two ports are divided by the blades of the impeller into a gas suction space from small to large and a gas compression space from large to small. With the high-speed rotation of the impeller and the continuous suction and compression of gas, the gas that needs to be processed is sent to the outlet pipeline of the compressor.

2、 Characteristics of liquid ring compressor

Unlike other types of compressors, the liquid ring compressor uses the sealing liquid in the casing as the working medium, making it a variable volume compressor. The blades of the impeller transmit centrifugal force to the sealing liquid, generating suction and compression forces similar to those of a piston. Its main features are as follows:

1. Gas and liquid can be mixed and transported. The liquid carried in the inhaled gas will not have any adverse effects on the normal operation of the compressor;

2. The configuration of gas inlet and outlet pipelines is simple and easy to operate and manage;

3. With appropriate control of the sealing liquid temperature, the temperature rise of the processed gas during suction and compression discharge is small and the exhaust temperature is low, without the need for a complex gas cooling system;

4. The structure of the liquid ring compressor is simple, with only one rotating component, no metal contact, few failures and easy maintenance;

5. Due to the high-speed rotation and continuous suction of compressed gas by this compressor, there will be no significant fluctuations in its outlet pressure and flow rate;

6. Liquid ring compressors are particularly suitable for handling gases that are easily decomposed at high temperatures, flammable and explosive gases, gases that do not contain solid particles and are insoluble or slightly soluble in sealing liquids and corrosive gases.

3、 Single action liquid ring compressor and double action liquid ring compressor

There are two types of liquid ring compressors: single action liquid ring compressors and double action liquid ring compressors. Although both types of liquid ring compressors are used for gas compression and transportation, there are some differences in construction, function, and application.

1. Single action liquid ring compressor

The structural feature of a single action liquid ring compressor (or flat port plate compressor) is that the impeller is eccentrically installed inside the compressor housing and a flat port plate is equipped with a gas suction port and a gas compression & discharge port. The impeller only produces one gas suction and compression process per rotation.

2. Double action liquid ring compressor

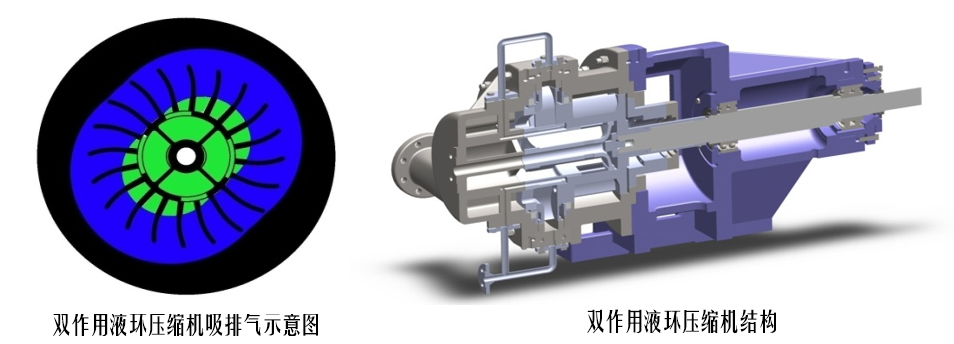

With the development of product design and manufacturing technology, there have been innovations in the structural design of liquid ring compressors. The new type of liquid ring compressor replaces the original flat port plate with a conical or cylindrical structure and sets up two sets of suction and exhaust ports on the distributor. The impeller of the compressor is designed to rotate around the gas distributor; In order to comply with the structural design concept of dual suction and dual exhaust of the gas distributor and fully utilize the impeller, the housing of the dual action liquid ring compressor is also optimized as a dual eccentric structure.

Due to these innovative structural changes, the impeller of the new compressor can achieve two gas suction and compression functions per revolution. This new type of liquid ring compressor is called a double action liquid ring compressor.

3. Comparison between double action liquid ring compressor and single action liquid ring compressor

Compared with single action liquid ring compressors, double action liquid ring compressors have the characteristics of a larger gas distributor opening and an expanded intake area, so they have stronger gas suction capabilities.

The increase in liquid content in the inhaled gas will have an impact on the working efficiency of the liquid ring compressor. Under the same working conditions, the efficiency decrease of the double action liquid ring compressor is smaller than that of the single action liquid ring compressor. In the presence of a condensable body, the double action liquid ring compressor is insensitive to the presence of water vapor in the intake and its pumping capacity can be greatly improved by condensing first and then compressing.

Due to the difference in intake structure, the double action liquid ring compressor has a greater advantage in operating energy consumption under the same working conditions. The energy-saving effect is particularly obvious during periods of high intake moisture content. Under the same suction volume, the power consumption of the double action liquid ring compressor is lower than that of the single action liquid ring compressor.

The suction port of a single action liquid ring compressor is generally located at the top of the compressor, and its impeller is eccentrically installed above the axis centerline; Due to the high sealing liquid level at rest, the starting current is relatively high. The position of the suction and discharge ports of the double action liquid ring compressor and the liquid level of the sealing liquid are relatively low, resulting in a smaller starting current.

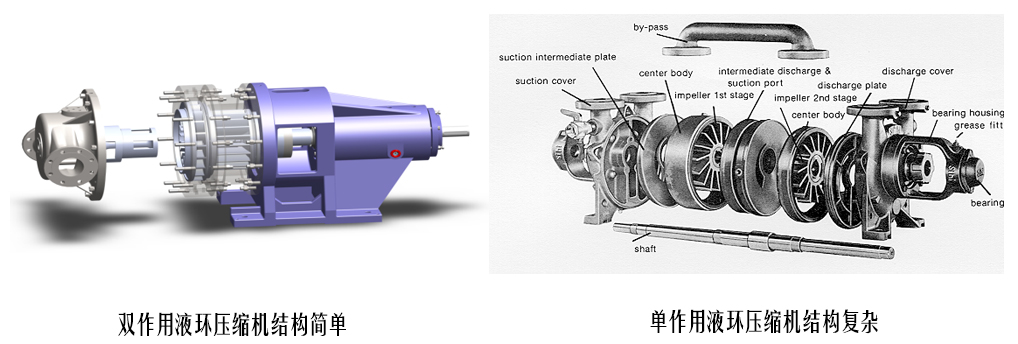

A single action liquid ring compressor needs to be designed as a two-stage structure when obtaining high gas discharge pressure. In this case, its structure becomes more complex, with an increase in the number of connected first stage and second stage impellers and low-pressure and high-pressure shell components divided into two by partitions in the middle. At the same time, there are more sealing points that need to be prevented from leakage, resulting in an increase in failure points. Compared to this, the two-stage structure of the double action liquid ring compressor designed to obtain higher delivery pressure is extremely simple. Its first and second stage impellers are connected in series by two impellers of different diameters and share a distributor corresponding to the second stage gas compression. This type of double action two-stage liquid ring compressor has fewer components, fewer sealing surfaces and fewer failure points.

The rotor of the double action liquid ring compressor adopts a radial force balance design, which ensures that the force balance is not easily damaged during high-speed rotation. During the selection process of the rotor for a single action liquid ring compressor, it is greatly affected by radial forces, and long-term use carries the risk of rapid rotor damage and shaft breakage.

In summary, compared with single action liquid ring compressors, double action liquid ring compressors have adopted many innovative changes in structural design, with many advantages such as large pumping capacity, energy saving, safety and reliability, and long service life. Therefore, it has more advantages under the conditions of compressing process gases that are corrosive or carry liquids.

4. The applications of liquid ring compressor

Widely applicable in:

Compression of flammable and explosive gases such as acetylene and hydrogen and compression of toxic and corrosive gases such as chlorine

VCM recovery in PVC plant and top vacuum system in crude oil vacuum distillation

Tail gas/flare gas recovery, circulating gas compression, pressure swing adsorption (PSA), vacuum conveying of various materials, polyester production, liquid chlorine production

- 5. Product Promotion

NIKUNI double action liquid ring compressor is a cylindrical gas distributor structure compressor, which has the characteristics of easy machining accuracy guarantee, easier assembly accuracy and clearance control, and more convenient maintenance service compared to the vertebral body liquid ring compressor. At the same time, the two stage version of NIKUNI double action liquid ring compressors also adopts a patented design of impeller dynamic self balancing, which has unique advantages in protecting the compressor rotor, bearings and mechanical seals.

The current maximum working range of the NIKUNI double action liquid ring compressor is: the highest suction capacity can reach 2500 cubic meters per hour and the highest discharge pressure can reach 5.5 kilograms in a single stage and 14 kilograms in a double stage.