The petrochemical and fine chemical industries have a high demand for small flow and high head chemical process pumps. However, due to the scarcity of pump products suitable for such conditions, especially for use as chemical process pumps, many domestic chemical equipment manufacturers and users often have to use centrifugal pumps, reciprocating pumps (including metering pumps), gear pumps, or high-speed pumps to meet their respective equipment needs. This approach, taken out of helplessness, actually poses many unavoidable problems for chemical equipment.

1. Problems with using centrifugal pumps

When centrifugal pumps are being used in small flow and high head applications, as they are originally designed for large flow applications, it is often necessary to divert some or even most of the liquid through branch pipelines to meet the needs of small flow. This approach not only has problems such as bulky pump volume, high motor power consumption, thick pipeline, complex reflux structure, and difficult control, but also has problems such as high initial equipment investment and high long-term operation and maintenance costs.

When multi-stage centrifugal pumps are used to achieve high head, it is inevitable that there will be problems such as complex structure of multi-stage pumps, large operating inertia that is not suitable for sudden starts and stops and frequent misfunctions.

2. Problems with using reciprocating pumps

Although reciprocating pumps have the characteristic of easily achieving high head, their reciprocating motion inevitably causes high pulsation, which cannot be completely eliminated even with a stabilizer (or accumulator). At the same time, when transporting high-temperature and impurity containing liquids, reciprocating pumps (plunger pumps) often have problems such as frequent failures and high maintenance costs. Therefore, reciprocating pumps are generally not suitable for operating conditions that require high stability in liquid delivery.

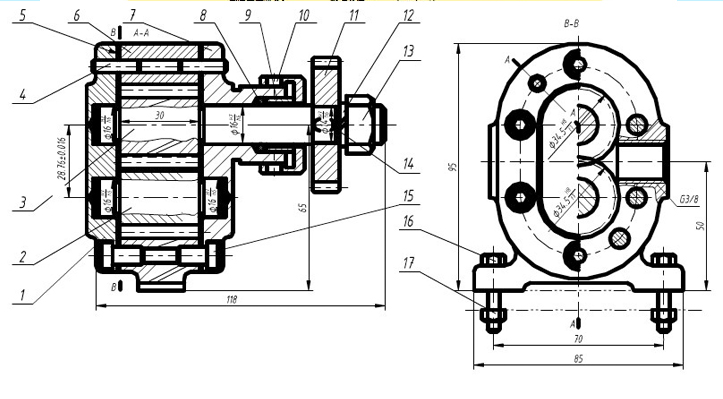

3. Problems with using gear pumps

Due to the contact friction between gears, gear pumps often experience performance degradation caused by gear wear during use, and are not suitable for transporting high-temperature liquids due to limitations in metal expansion coefficients.

4. Problems with using high-speed pumps

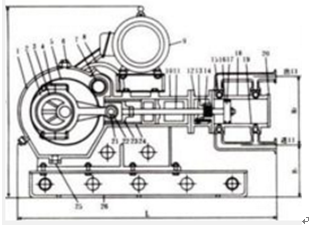

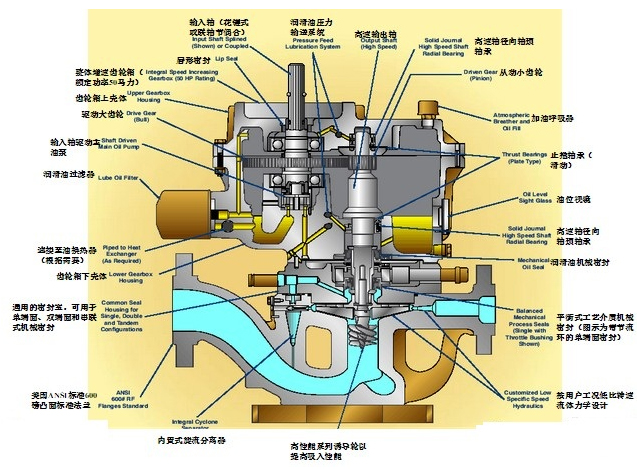

The speed range of the high-speed pump is between 3500-25000 rpm, driven by an integral gearbox. The structure of the integral gearbox is complex and in order to control vibration and noise levels, high machining accuracy and overall fitting accuracy of the constituent parts are required. At the same time, a forced lubrication system is also needed to ensure its normal operation. High speed pumps not only have high production costs and expensive prices, but also require complex maintenance and correspondingly high repair costs.

一. 1. Regenerative turbine pumps are suitable for small flow and high head applications in chemical processes

In working conditions of small flow and high head liquid transfer, NIKUNI regenerative turbine pump has advantages that cannot be replaced by the above-mentioned pumps. The main features of the NIKUNI regenerative turbine pump are as follows:

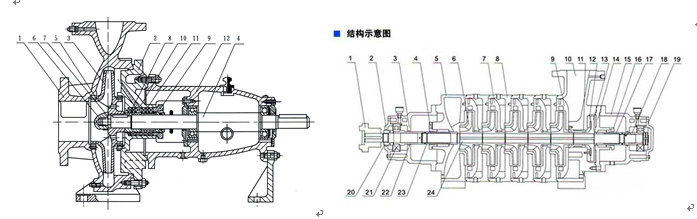

1. Compact size and simple structure

NIKUNI regenerative turbine pump features fewer wet components, small size, simple structure and easy maintenance and repair.

2. Suitable for complex and demanding usage conditions

NIKUNI has a full lineup of regenerative turbine pumps which are designed and manufactured according to special operating conditions, with good resistance to gas corrosion, high temperature, and suitable for gas-liquid mixture transportation. They are especially suitable for harsh operating conditions such as small flow, high head, etc. that other pumps find hard to cope with in chemical processes.

3. Reasonable design, high quality and long-term stable performance

After more than 70 years of continuous improvement and optimization, the unique design and excellent performance of the NIKUNI regenerative turbine pump are at the forefront of the world. Strict material control and precision machining with CNC equipment provide reliable guarantees for product accuracy and quality.

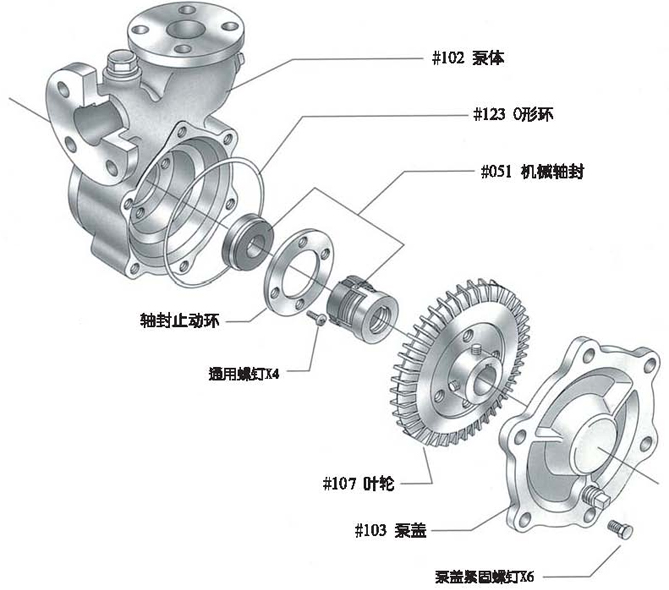

The biggest difference between NIKUNI regenerative turbine pumps and similar products by other pump manufacturers lies in the fixing method of its impeller. NIKUNI ensures the concentricity and parallelism of the pump shaft and impeller through precision machining and fixes the impeller of the pump at the shaft end, strictly controlling the clearances between the impeller and the pump body. Apart from the mechanical seal of the rotating components, there is no direct contact or friction between the parts of the pump during operation, ensuring the long-term stability of the pump's performance.

4. Rich product lineup and wide corresponding scope

NIKUNI has developed numerous series of products to meet the needs of industrial development, including high temperature, low temperature, low melting point, low flash point, easy boiling, flammable and explosive, highly toxic, radioactive, ultra clean and valuable fluids. The high self-priming variety (~8 meters), ultra-low NPSH (0.3 meters), heat medium variety (~350 ℃ without cooling), gas-liquid or liquid-liquid mixed transportation variety, and leak free variety of loaded magnetic drives in its chemical process pump varieties have been widely used in the domestic petrochemical and fine chemical industries.

A single-stage impeller of the NIKUNI regenerative turbine pump can achieve a pressure of~17 kilograms, while double stage impellers can achieve a pressure of~30 kilograms; The inlet port diameter of the pump varies from 15 to 100 millimeters, making it easy for users to choose within the flow range of 0.1 to 50 cubic meters.

According to actual needs, NIKUNI can also customize products that comply with API610 specifications for users.

二. Application of NIKUNI regenerative turbine Pump in Chemical Processes

1. In the production process of chemical product sulfoxide, it is necessary to transport media that are easily gasified and contain impurities. Centrifugal pumps have low gasification resistance and are difficult to meet the production process requirements. Due to the replacement of the original centrifugal pump with a NIKUNI regenerative turbine pump by the user, the frequent malfunctions and pump damage that caused serious economic losses during the production process have been completely resolved. At present, NIKUNI regenerative turbine pump has become one of the key equipment in the production process of sulfoxides.

2. The conventional production process of ammonia methanol requires a complex mixed reaction process and requires the use of various large equipment (pumps, valves, reaction vessels, etc.) to achieve product integration production process. The conventional production process faces difficulties such as expensive production equipment, difficult operation and maintenance, environmental pollution caused by gas leaks and long-term high production costs.

After users replaced the original mixed reaction process and related equipment with NIKUNI regenerative turbine pumps, they not only easily achieved the goal of simplifying the process, but also reduced equipment investment and production costs, while fundamentally solving the problem of environmental pollution.