Ozone has a strong oxidizing ability. It has the functions of decomposing organic pollutants, killing bacteria and toxic substances, and decomposing various polluted gases. Ozone oxidizes after several hours of use, and there is no residual secondary pollution from other disinfectants such as chlorine dioxide. Therefore, it is widely used as a pollution-free clean treatment source for sterilization, deodorization, decolorization, and other purposes. The application of ozone is divided into two types: gas phase and liquid phase.

In the liquid-phase application of ozone, the more traditional and widely used process is ozone generator + booster pump + ejector + oxidation contact tower. In addition, there is another process of directly mixing ozone inside the pump, which is the NIKUNI aeration pump process. Below is a brief introduction to the characteristics of the NIKUNI aeration pump and its performance comparison with traditional mixing processes.

Application of NIKUNI Pump in Ozone Water Production

NIKUNI aeration pump is a model of the exquisite combination of NIKUNI industrial pump design technology and precision machining technology. Its unique design and excellent performance provide a more efficient and ideal choice for ozone water treatment technology.

- 1. Characteristics of NIKUNI aeration pump:

◎ High dissolution efficiency

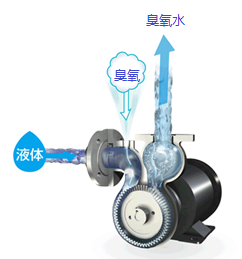

As shown in the figure on the right, there are dozens of radially arranged blades around the impeller of the NIKUNI aeration pump, which generate friction and thrust during the rotation of the impeller inside the pump. The gas-liquid mixture sucked into the pump by negative pressure is vortex pressurized and mixed between each blade. During the process from the inlet to the outlet of the pump, ozone has been uniformly mixed dozens of times, so it can be fully dissolved in water.

◎ Long term performance stability

NIKUNI pump has a simple structure, with no metal friction parts inside except for the mechanical seal. In addition, the pump is made of 304 or 316 stainless steel, and the sealing material is high-quality silicon carbide and PTFE, which has excellent corrosion resistance.

In addition, the low NPSH design of the NIKUNI pump ensures smooth gas suction and mixing, with long-term stable and reliable performance.

◎ Small foot print saves installation space

NIKUNI pump has a reasonable structure and small volume. Even in the production of 50 cubic meters of ozone water equipment, the land area of the NIKUNI aeration device does not take big floor space and the device height can also be small enough. Especially suitable for current equipment renovation and equipment setup in existing factories.

Easy to operate and maintain

NIKUNI aeration device is simple in structure. After adjusting the water volume, ozone generation, oxygen volume, and operating pressure appropriately, it can operate a long time without failure and basically does not require maintenance.

2. Application effect of NIKUNI aeration pump

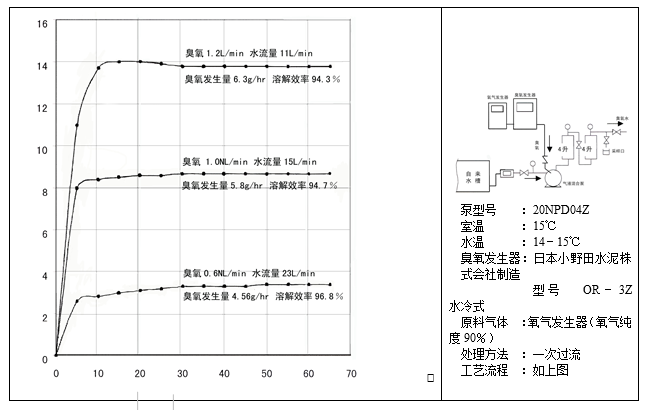

Based on the output and concentration of the ozone generator, the amount of treated water, the amount of oxygen inhaled, and the water temperature, the dissolution efficiency of ozone in water can reach over 99% by using a NIKUNI pump. Please refer to our company's application test report.

Low operating costs (electricity), users can get more benefits.

Suitable for producing high concentration ozone water

In industries such as sewage treatment and semiconductor cleaning that require the production of high concentration ozone water, traditional processes require repeated mixing and extended contact time to achieve the desired results. As a result, the large amount of ozone generators and large oxidation contact towers increase the cost of the entire treatment equipment, and the equipment's footprint becomes quite large, and the treatment effect is not ideal. The mixing process using a NIKUNI aeration pump can achieve ideal treatment results while improving mixing efficiency and shortening mixing time.

limitations

The gas water mixing ratio of the NIKUNI aeration pump is 1:9, which means that gas takes about 10% of the pump's flow rate and remaining 90% of the flow rate is liquid. Therefore, it is generally only applicable for producing ozone water using pure oxygen sources. This to some extent limits the application of NIKUNI pumps in equipment for producing ozone water from dry air sources.

However, considering that the oxygen purity of the dry air oxygen source is about 21%, and the remaining 79% inevitably transforms into residual nitrogen compounds, it is not suitable for use in pure drinking water (in foreign countries, pure oxygen sources are generally used to produce ozone water). Furthermore, due to the fact that the oxygen purity of dry air sources is more than three times lower than that of pure oxygen sources, the amount of ozone generator required to produce the same amount of water is correspondingly increased, thereby increasing the investment and operating costs of ozone generators.

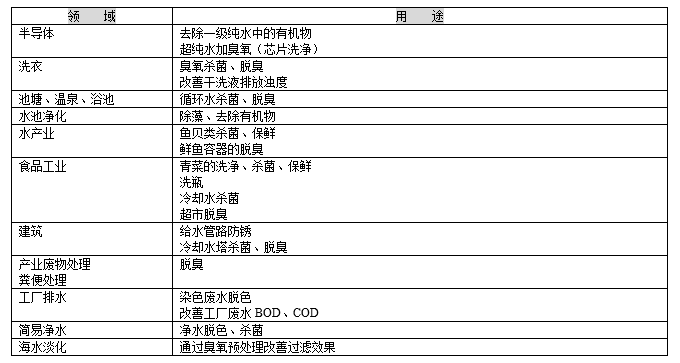

4. Application fields of NIKUNI aeration pump

NIKUNI pumps have won high praise from ozone users in Japan due to their efficient mixing characteristics and have achieved absolute market share in the Japanese market. Almost all small and medium-sized ozone tax production equipment uses NIKUNI pumps. In recent years, especially in application fields that require high concentration ozone water, especially in the microelectronics industry where chip cleaning requires a concentration close to 200ppm, traditional mixing methods are simply unable to cope, and the only solution is the NIKUNI pump (PTFE coated product).

Since its sale in China, tens of thousands of users (including equipment manufacturers and engineering companies) have adopted NIKUNI aeration pump. A considerable number of users have switched to NIKUNI pumps due to the modification of existing equipment or the inability of traditional equipment to meet quarantine standards. So far, the renovation rate is zero.

5. Scope of Supply

尼可尼泵的供货范围0.5-120立方/小时。单泵或成套设备供应均可。欢迎与我们接洽。